Natural Gas, from Well to Consumer

5 min read

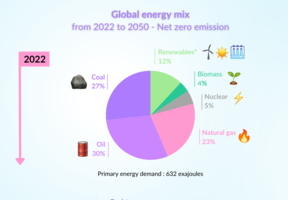

Natural gas is a strategic source of energy in the world today, a fact highlighted by the war in Ukraine. It is often considered as a transition energy, as it generates less pollution than other fossil energies and has many different uses. Here’s how natural gas is extracted, processed, stored and distributed, from production to consumption. A process referred to as the gas “value chain”.

Onshore and Offshore Production

Formed over millions of years from organic sediments, natural gas is extracted from subsurface reservoirs, either under the surface of the land ( ), or under the sea ( ). The operation consists in bringing the gas back up to the surface by a well, sometimes down to depths of 6,000 meters.

After separating different products, the gas which is essentially , is channeled to the transport facilities. Gas is transported either in its gaseous state, through onshore or subsea gas pipelines, or in its liquid state, by LNG carriers.

Gas Transport by Pipeline

Pipelines are still the main mode of transportation for natural gas, particularly on the same continent. There are onshore pipelines, like those making up the Russian network and its external extensions. Gas pipelines are usually buried for safety reasons. The gas has to be compressed every 150 km in compression stations, to ensure that it circulates at a speed of 15 to 20 km/h. There are also subsea pipelines, such as those linking Norwegian gas deposits to European terminals. Pipeline gas is transmitted from one point to the next, according to set routes, between partner companies bound by long-term contracts.

Transport in Liquid State by LNG Carriers

Conversely, transporting gas in its liquid phase - LNG, Liquefied Natural Gas - offers considerable flexibility. The vessels transporting it can even change their itinerary depending on the purchases and sales made at a given time. The war in Ukraine has forced European countries to replace Russian gas received via pipelines, by LNG from the United States or the Gulf, delivered by LNG carriers. The gas has to be converted into the liquid state, at a temperature of around -160°C. This process is done in plants. LNG takes up 600 times less volume than in its gaseous state, but keeps the same properties: it is colorless, non-toxic and non-inflammable in the absence of oxygen. It is then loaded onto specific vessels called methane carriers.

The Rapid Expansion of LNG Carriers

The use of LNG is becoming more and more widespread. In 2022, around 700 LNG carriers were sailing the world’s oceans and 200 were on order, mainly in the South-Korean shipyards. These huge vessels, measuring 200 to 350 m long, transport up to 260,000 m3 of LNG. They are able to keep it at -160°C for thousands of kilometers.

The most frequently used type of vessel is called a “membrane carrier”, whose tanks are part of the double hull structure. There are also LNG carriers with four or five spherical aluminum tanks that can be seen just above the hull, but these carry a lower volume.

Regasification of Natural Gas

Once it has arrived at the destination terminal, the LNG is regasified by increasing its temperature using either the from the seawater, or by heating water. Finally, the gas is fed into the transport network of the country in question.

To speed up the process and for greater flexibility, companies are installing more and more floating terminals for LNG carriers, anchored away from the ports, to receive and regasify the LNG. These Floating Storage and Regasification Units (FSRU) are often former LNG carriers that receive equipment for transhipment, gas processing on board and the connection to the onshore distribution network.

Gas Storage

Consumption of natural gas varies with the seasons and with heating requirements. For example, the French population consumes eight times more natural gas in winter than in summer, so natural gas needs to be stored in order to balance supply and demand.

Storage in giant tanks is not a long-term storage solution. The answer is to store the gas in a natural subsurface reservoir, a bit like if we were to create an artificial gas field.

The most commonly used method is storage in water-bearing layers: the gas is injected into a subsurface layer of porous rock containing water and capped with an impermeable layer. This way, large quantities of gas can be stored. In France for example, a third of annual gas consumption can be stored in subsurface reservoirs.

The many Uses of Gas

Natural gas has many uses. In Europe, 55% of gas consumption is taken up by generating for different industries, in particular petrochemicals and the transport industry. It is a high-yield, highly versatile source of energy, and the emissions are twice as low as those produced by a -fired station.

It is also widely used in homes for heating, producing hot water and cooking. 40% of natural gas consumption in Europe - 21% worldwide - is attributable to the residential/tertiary sector.

This may interest you

This may interest you

See all