The transformation of microalgae biomass: energy for the future?

10 min read

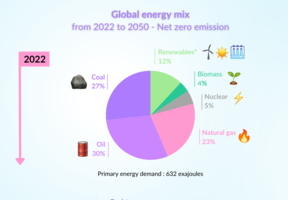

Microalgae are considered a third-generation source because they do not compete with food crops and can grow on non-arable land. They capture CO₂ and contribute to reducing greenhouse gaz emissions, but their large-scale exploitation remains an economic challenge.

© - Microalgae cultivation ponds at the Le Vigeant site near Poitiers in central France – home to a research center for algal biomass conversion. ©AFP

Algal biomass: considerable potential

Among the hundreds of thousands of microalgae species found in nature, around 300 have already been identified for their ability to produce oils in large quantities. Their use has begun in certain sectors, with small-scale production of high value-added products such as pigments and omega-3. Prospects are emerging for animal feed and specialty chemicals. However, mass energy production of biofuels and biomethane is currently only at the research and development stage, and it will take at least ten years to achieve sufficient economic profitability.

Micro-factories thanks to biotechnology

Selected through biotechnology, microalgae become true “factories” that produce oils according to a programmed process.

Plants, whether terrestrial or marine, accumulate energy reserves in the form of oils and sugars to ensure their survival in all situations. Compared with natural species selection, the application of biotechnology to microalgae—and also to —enables a significant qualitative leap: it paves the way for the production of mutant species that are capable of “over-accumulating” a specific element that is useful to humans. The selected species then becomes a veritable “factory” that produces what humans have ordered. The selected microalgae then yield much higher per-hectare output than terrestrial plant species. This scientific promise explains the immense research effort that has been undertaken around the world.

Culture and extraction

The first step is therefore to select the strains best suited to naturally producing oils, then optimize their metabolism through genetic modification to improve yield. The second step involves cultivating them in large outdoor ponds or in “bioreactors” consisting of transparent tubes. After harvesting, the proteins, lipids, and carbohydrates are extracted. The lipids are then converted into biofuels.

How is microalgae biomass converted into biofuels?

The methods used to convert algal oil into biofuel are similar to those used for conventional vegetable oils:

• Esterification, which involves reacting the algal oil with or ethanol, produces that can be blended to fuel.

• Catalytic hydrogenation, which reacts the oil with hydrogen, followed by , produces hydrocarbons that can be blended into diesel or kerosene.

• Other biochemical and thermochemical processes can be used to produce ethanol or hydrocarbons that can be blended with gasoline and diesel.

Advantages and disadvantages of microalgae processing:

The processing of microalgae offers advantages over terrestrial :

• Yields per hectare are much higher than those of oil crops (rapeseed, oil palm). At the laboratory stage, oil productivity per hectare has been 20 to 30 times higher than that for terrestrial oil crops.

• Cultivation areas do not need to be arable and therefore do not compete with agricultural land.

• The growth of lipid algae requires large amounts of CO₂, which opens up prospects for recycling CO₂ emitted by factories or thermal plants.

However, there are several challenges to mass production:

• The crop requires specific conditions in terms of sunlight and water availability, which limits the possible locations.

• It also requires large amounts of nutrients (nitrates and phosphates) and carbon dioxide, while oil extraction consumes a lot of energy.

• A whole logistics infrastructure, which does not currently exist, will also be needed to supply the new farms with the raw materials and energy they require.

• Even under the best sunlight conditions, cultivation requires large areas of land to achieve significant production levels. It is estimated that farming an area of 150 km² – equivalent to the Arcachon basin – would produce one tenth of the output of a large conventional French oil refinery.

• The production costs of algae-based biodiesel are currently estimated at between €5 and €10 per liter, making commercial production impossible at present. However, more than $2 billion in investments and over 200 research and development projects have been identified, mainly in the United States, but also in Europe and China.