Focus on Photovoltaic Solar Energy

10 min read

Focus on ( , thin film and perovskite technologies). Benoît Lombardet and Daniel Lincot offer their analyses.

Benoît Lombardet

The Growth of Photovoltaic Solar Energy Around the World

Is the growth of photovoltaic (PV) solar energy worldwide limitless? The use of silicon-based solar cells has been rising exponentially for 15 years and new technologies are unveiling promising opportunities. Benoît Lombardet, R&D Director, OneTech at TotalEnergies, analyzes the future of this up-and-coming source of energy.

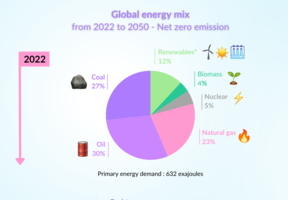

Photovoltaic solar technology has been making a rapidly growing contribution to the global energy scene for some 15 years now, as measured by in gigawatts (GW), i.e., billions of watts. Over 100 gigawatts were installed in 2018, pushing the world above the 500‑gigawatt threshold of aggregate installed photovoltaic capacity. The outlook for 2030 varies significantly, from 1,300 gigawatts for the least optimistic to 5,000 gigawatts for the most optimistic, i.e., between 1.3 and 5 terawatts (TW, trillions of watts). The change from gigawatts to terawatts says it all...

Germany got the ball rolling, but development in the sector is now being driven by the two most populous countries in the world: China, followed well behind by India. The United States and Europe come next, both also increasing their contribution at a steady pace. The world’s growing demand for energy, especially electricity, and awareness of have accelerated the development of renewable energies such as solar and wind, now competitive with traditional sources. Photovoltaic solar capacity is today equally divided between large solar farms and building-integrated systems.

Are There Limits to PV Development?

There are no limits to PV development in terms of materials. The dominant technology currently used (over 95%) is based on silicon, the second most abundant element on Earth. Metals (copper, aluminum and silver) are also used to extract the electricity from the solar cells and panels. The only element that may restrict the development of the sector is silver, but as technology improves, the quantities needed to produce a are rapidly dropping. Thin-film technologies use much rarer elements such as indium and gallium, so production may be slowed down depending on their availability. However, the growth of thin films is today mainly limited by the attractiveness of the silicon industry, which has created a hugely powerful, standardized ecosystem with extremely competitive production costs thanks to its scale and volumes, forming a high barrier to entry for newcomers.

Significance of Long-Term Costs

Cost is an important question when it comes to developing these industries. It is closely linked to the production ecosystem. Since 1976, each time global production capacity has doubled, production costs have dropped an average of 24%. This trend has even sped up since 2008, with an annual decrease of between 10% and 20%. Stakeholders in the silicon industry have taken advantage of this economic relationship and continue to improve the performance of their products, even if they are getting closer to the theoretical limits.

The development of a new family of highly promising photovoltaic materials, perovskites, may lead to a breakthrough in the next few years. Perovskite-based solutions are easier to manufacture than their silicon equivalents, as well as being inexpensive and highly efficient. In light of this high potential, considerable research has gone into the new technology, resulting in spectacular progress. Purely based on performance in the laboratory, perovskites now achieve similar levels of efficiency to silicon. However, their long-term stability is still too limited and much improvement is needed for them to offer an attractive alternative to silicon technologies that can guarantee performance for 25 years.

Limits to the Silicon Industry

There are obviously limits to the development of the silicon industry.

Firstly, logistics: many new production plants and supply chains need to be set up to be able to produce several hundred gigawatts per year, and the energy used to power them must be .

The second limit is related to the first: availability of investments. Currently, around €500 million needs to be invested along the entire value chain to increase production capacity by 1 gigawatt per year. It is very difficult for solar panel manufacturers to make money when there is a price war in the industry and costs are falling. Motivating investors when profitability is low is far from easy, even in China...

Lastly, as has often been pointed out, power grids must be adapted so they can absorb the increasing amounts of renewable electricity from sources that are intermittent by nature. Storage capacity needs to be developed and the way we manage the power grid and consumption needs to be completely rethought to be able to exceed penetration of 20%.

To sum up, the growth of photovoltaic technology goes hand in hand with the development of solutions for electricity storage (batteries, , etc.) and for the smart management of increasingly complex power grids.

Born in 1977 and a graduate of the École Polytechnique, Benoît Lombardet has been Electricity R&D Director, OneTech at TotalEnergies since September 2021.

Daniel Lincot

Photovoltaics: The Long Chain From Research to Industry

The photovoltaic (PV) solar energy sector is underpinned by intensely active global research and a constantly expanding market. Daniel Lincot, Emeritus Director of Research at the CNRS, explains the strategic nexus between research and industry.

Research in the field of solar photovoltaics is thriving across the world owing to the sheer breadth of its scope. The spectrum covers fundamental research into the interaction of light photons with matter, to innovation for industrial applications; hence, from quantum physics to the composition of resins for encapsulating PV cells, making them last longer.

From researcher to solar system installer and laboratory to market, a long chain runs from academia through to industry, providing an astonishing boost to the sector’s technological progress. Its role is vital – every link counts.

The Main Solar Cell Categories

It all started with so-called first-generation technology based on silicon. Accounting for more than 95% of the global market with constantly falling costs, this is still the dominant technology. The PV modules are often made from monocrystalline silicon cells, with maximum efficiency1 above 25% in lab conditions (250 watts per square meter for 1,000 watts of incident energy in the form of sunlight). The Japanese set the world record at 26.6%. The cells can also be made from the more easily manufactured and deeper blue-colored polycrystalline silicon, but its efficiency is lower, at about 22% in the lab2.

Rather than slicing thin “wafers” of around 0.2 millimeters (200 microns) from a silicon bar, researchers realized early on that it would be better to produce the solar cells using thin layers of photovoltaic material deposited directly on a cheap substratum, like glass. The resulting thin films, scarcely a few microns thick and 100 times slimmer than silicon wafers, are used with copper indium gallium selenide (CIGS). At about 23% efficiency3, they outperform polycrystalline silicon. Another technology, using cadmium telluride (CdTe), is over 22% efficient in the lab4. Thin-film technologies, whose global market share verges on 5%, are nearly as efficient as silicon varieties and are therefore gradually gaining ground. Moreover, their manufacturing process is less complex, hence less costly once they hit large-scale production.

However, thin-film techniques were in turn disrupted a few years ago by the spectacular progress of organic solar cells (containing carbon), marking the beginning of organic photovoltaics (OPVs), similar to organic LEDs (OLEDs) in the lighting sector. These printable solar cells stem from concepts and techniques used by chemists. They work using colored molecules, which function in a way similar to natural . It is a potentially low-cost technology best suited to niche markets with a current efficiency of about 6%, but growing steadily.

Over the last five years, thriving photovoltaic research has produced a truly stellar performer: perovskites, an intermediary “hybrid” blending standard and organic materials, based on methylammonium lead iodide. Perovskites have achieved over 23% efficiency in lab conditions in Switzerland, South Korea and China5, and despite some research problems yet to be resolved, their future is full of promise.

Toward Multi-Junction Cells

Technological progress in photovoltaic energy comes in successive waves, not small, steady steps. More disruptive innovation is just around the corner. Researchers worldwide are competing in an efficiency race and the winner will come as no surprise: multi-junction solar cells, which are set to replace the single-junction cells used today. For example, if silicon solar cells were deposited on suitable thin-film cells, the result would be a double junction, a “tandem” cell with potential 43% efficiency – a huge leap ahead. Four-junction cell efficiency has already hit 46% in lab conditions.

Constantly looming large is the economic backdrop to this progress, making the end cost of the electricity generated a permanent concern. At the IPVF, we are working on a flagship program, worth mentioning because of the symbolism it carries. It is the 30-30-30 program: 30% efficiency by 2030 at a cost of 30 euro cents per watt. To reach this goal, we are focusing on “tandem” technologies combining silicon and thin-film techniques – a match made in heaven.

Daniel Lincot is Emeritus Research Director at the CNRS and Visiting Professor at the Collège de France. He was scientific director of the Institut Photovoltaïque d'Ile-de-France (IPVF) until 2019, when he retired. The IPVF, created in 2013, aims to improve the performance and competitiveness of photovoltaic cells. A graduate of ESPCI ParisTech, Daniel Lincot worked on the photoelectrochemistry of semiconductors and supervised the creation of an electrolysis production chain for thin-film solar cells.

- Efficiency is the ratio of electrical output to intake of incident energy from sunlight, expressed as a percentage.

- 22.3% record at the Fraunhofer Institute (ISE) in Germany.

- 23.35% record recently set at Solar Frontier in Japan.

- 22.1% at First Solar in the United States.

- 23.7% record.